The goal for the day was to get the transmission out of the car. The catch was that the driveline was still intact, so there were several things that needed to happen before I could access the transmission. First on the to-do list was dropping the driveshaft.

After getting the car up on jack stands the driveshaft removal only required removing the u-bolts on the u-joint at the third member. With the connection to the rear end severed I was able to slide the driveshaft yolk out of the back of the transmission and spill transmission fluid all over the floor, someday I’ll remember that side effect ahead of time and put a drip pan under it.

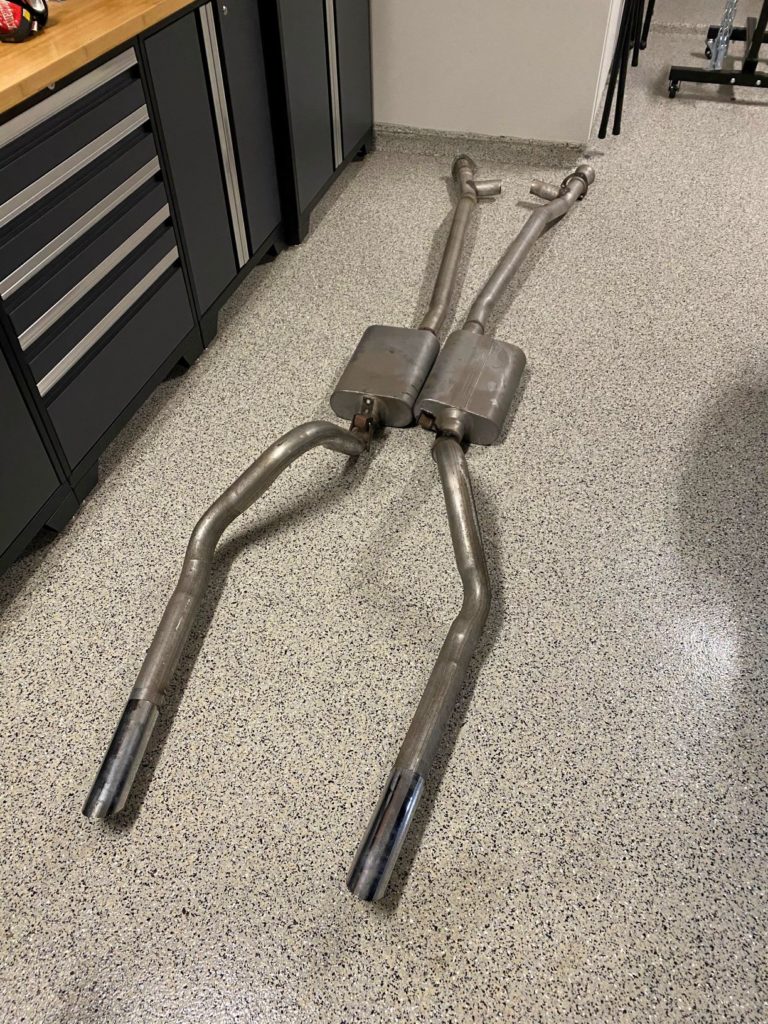

Thanks to the long tube headers and the convenient H-pipe placement directly behind the transmission crossmember the exhaust system needed to come out next.

Dropping the exhaust turned out to be more of a pain than I had initially anticipated. The last time that I had the exhaust off I had removed the entire rear end first but I wasn’t quite ready to do that this time, I still wanted the car to be able to be rolled around in the garage.

The primary issue was the combination of the H-pipe and the over-axle bend in the pipes. The bends were significant enough that there wasn’t an angle that I could get the pipes to that would allow them to clear the axle and the H-pipe prevented any useful rotation.

After disconnecting the exhaust system from the headers I tried all sorts of silly things to try and get the exhaust free – moving the jack stands to the rear frame rails in order to let the axle housing hang down, removing the rear shocks, and squeezing the pipes together with a ratcheting strap that allowed them to clear the leaf springs but not the axles. If I had a lift I likely could have gotten the car high enough to get an angle that would have allowed the pipes to come free but I was stuck working with what I had.

Eventually I conceded defeat to simple physics and broke out my new reciprocating air saw for the first time and sliced the H-pipe in half. Thankfully I wasn’t planning on re-using this exhaust system.

With the two halves separated I was able to twist them over the axle and out from under the car without too much effort.

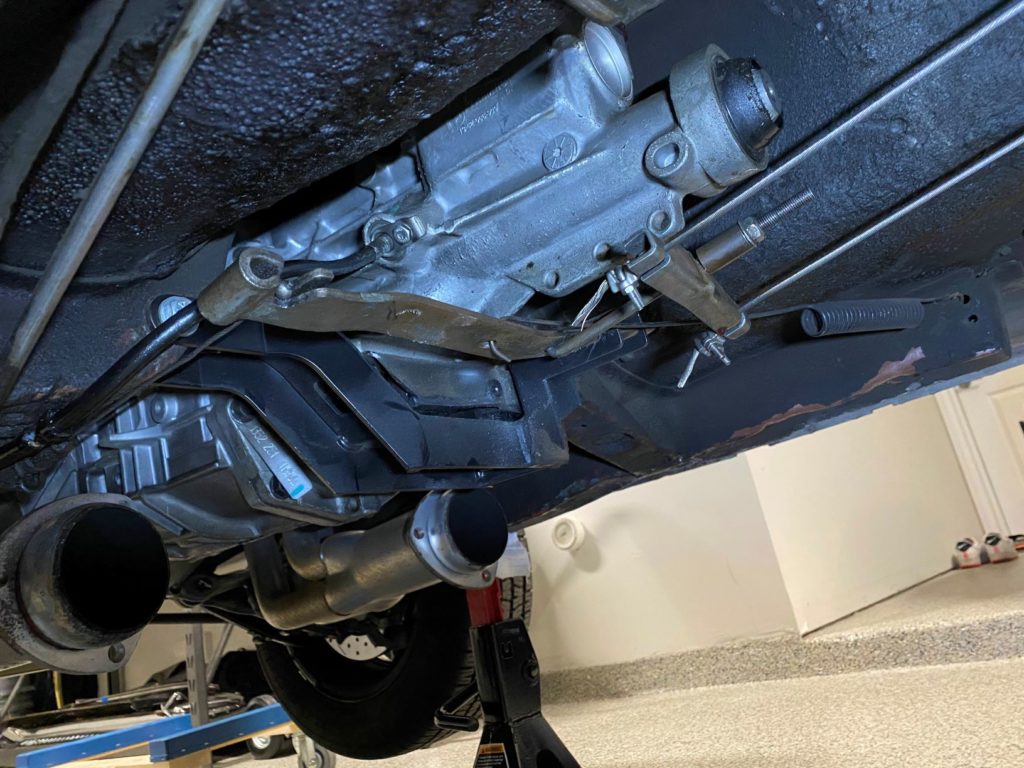

With the exhaust system finally down the next challenger was the emergency brake linkage as it relied on a lever arm which had its fulcrum on the transmission crossmember. Thankfully the e-brake on these cars is a pretty simple thing and disassembly didn’t take long.

It was time to drain the transmission fluid, undo the bolts connecting the transmission crossmember to the transmission, get the transmission jack in place, remove the bolts holding the transmission to the bellhousing, then remove the crossmember entirely and start to slide the transmission backwards so that the input shaft could clear the bellhousing before slowly lowering the jack to the ground.

Unfortunately I got only got to the third step as there wasn’t enough clearance between the headers to get the transmission jack in place.

Following the removal of the passenger side header I was able to get the jack in place and finish the preparations for squiggling the transmission out of the car.

Shifting the transmission into 3rd gear gave me just enough rear clearance in the shift lever hole to allow the input shaft to clear the bellhousing before lowering the transmission.

It took all day but the transmission was finally out!

Since the transmission doesn’t need any particular work at this point it will likely hang out on the jack in a corner of the garage until the rest of the project is completed and it’s time to re-install it in the car.

Nice! No catalytic convertors. Heck, leave the exhaust system off – those open headers look ready to growl!