The primary reason for this entire restoration finally arrived – addressing the rust. I decided to start with the trunk since it was both the most severely afflicted and the least likely to be visible at the end of the project, the perfect place to make inevitable mistakes as I learn how to do this kind of work.

I started by taking aim at the passenger side trunk floor, it seemed like the most degraded section of metal would likely be the easiest to remove.

To get things started I used the pneumatic hacksaw to cut out what remained of the spare tire tie down.

From there I started separating the panel at the upper seams by removing the spot welds with a blair spot weld cutter and a cordless drill. The cutting process itself is quite slow, requiring several minutes of concentrated effort on each spot weld. In some cases it can also be difficult to even figure out where the spot welds are, grinding away the primer and running a gloved finger over the exposed metal can sometimes reveal a likely spot weld that would be difficult to see otherwise.

I found that after the spot weld are cut I still needed to get something in between the panels to convince them to live separate lives. For the first week I was using a putty knife, after which I discovered purpose-built panel separators that were life changing.

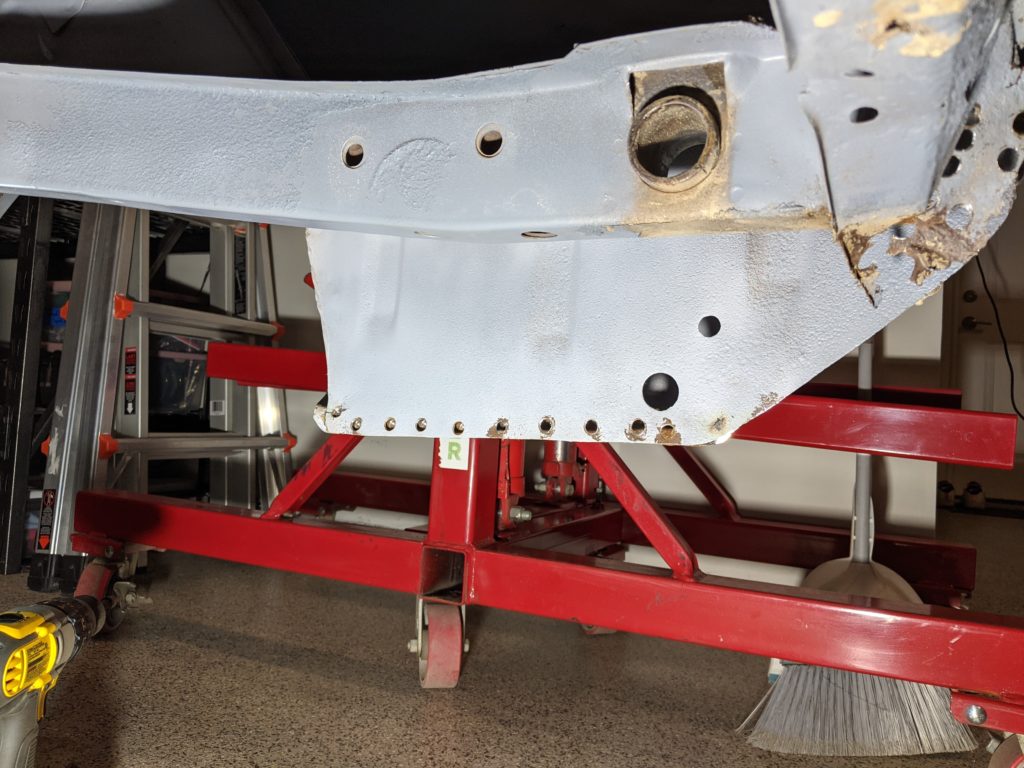

With the seams partially separated I was able to bend up a portion of the panel to form a crease at the end of the rear frame rail that runs underneath the trunk floor. With the help of the pneumatic hacksaw I cut along the crease in order to have better access to separate the rest of the panel from the frame rail.

Next up was cutting out the spot welds along the entire length of the panel where it met the frame rail underneath. About half of those spot welds were relatively easy to remove due to the rust damage causing the metal to be thinner so less cutting was required. A few of the welds up near the wheel housing were too awkward for the drill to reach and I had to use a cut off wheel to grind them down.

The panel also had a lip that bent down against the wheel housing where the two panels were mated by even more spot welds. Cutting those out was required before I could lift the trunk floor panel out.

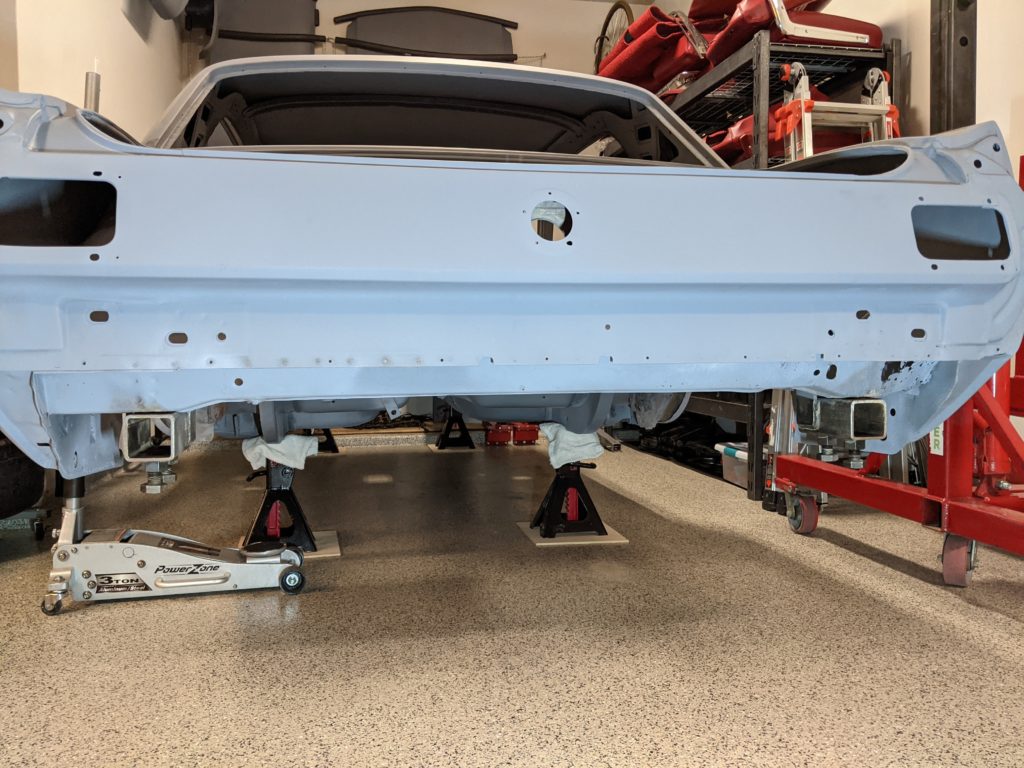

Finally – separation!

The bumper bracket against the tail light panel was particularly obnoxious to set free, it was welded both to the tail light panel and the trunk floor/frame rail below. The manner in which it was welded along the base rendered the spot weld cutter largely ineffective, a combination of a cut off wheel, die grinder, and patience eventually proved up to the challenge.

Despite some surface rust the frame rail continued to look solid through all of this, excellent news.

Next was cutting out all of the spot welds around the perimeter of the trunk drop-off panel on the inside of the bottom section of the quarter panel.

Pulling that free revealed a fair amount of rust at the seams of the outer wheel housing and at both the bottom and rear of the quarter panel. To-do list expanded.

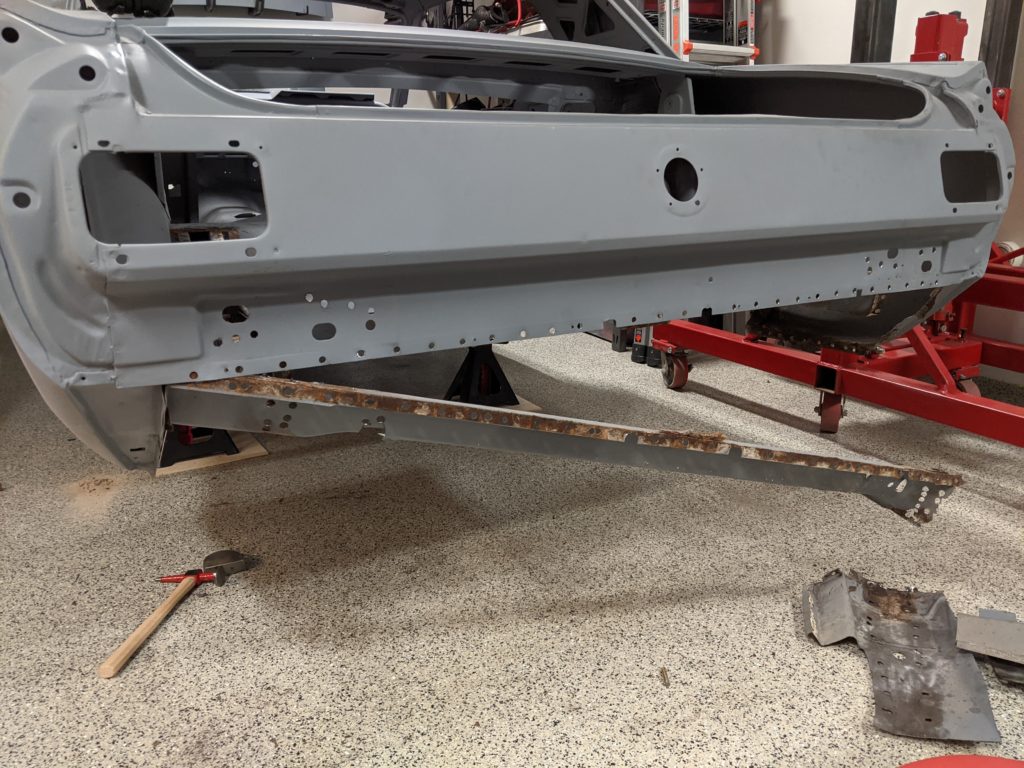

Time to rinse and repeat on the driver’s side, though the order of operations was slightly different due to less pervasive rust damage and me testing out alternative angles of attack.

One of the things that made the driver’s side go faster was that I had learned to consider whether I was actually planning on re-using the metal on the opposite side of the spot weld I was cutting out. If not then using a normal drill bit and cutting through both panels was no loss and progressed significantly faster.

Before and after.

The last piece to remove was the rear trunk brace. Though it didn’t look too bad after being covered in primer most of the panel was rotted through.

From here I’ll need to figure out exactly how I want to repair the damage I found on the passenger side quarter panel and wheel house seams (fabricate vs. buy pre-fab metal), as well as cleaning up some overly-ambitious spot weld cuts on the taillight panel and driver’s side inner wheel house. Once that’s sorted it will be time to start looking at welding in a new trunk floor.