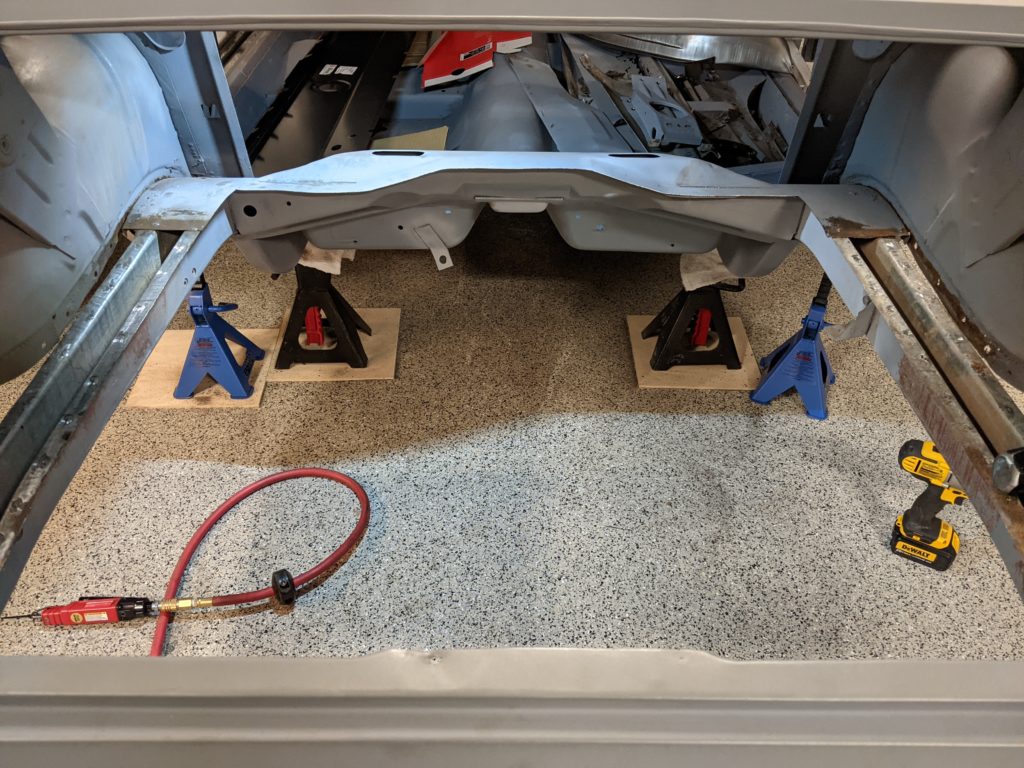

After coming to the conclusion that the quarter panels were going to need to be replaced I decided to switch gears and finish out the work in the trunk first. My thought was that while I still had the old quarter panels on (and most of the wheel wells) they would serve as useful guidelines for installing the new trunk floor. Then once the trunk floor was in place I could go ahead and remove the quarter panels and the new trunk floor would help serve as a reference.

The first order of business was to drill out the rest of the spot welds from the wheel wells back to the trunk floor. This went relatively quickly because I was able to use a drill bit to cut them out quickly since the plan is to replace the metal on both sides.

With the wheel well spot welds cut it was on to removing the spot welds that continued down along the frame rails and down to the shock mounts over the rear axle.

These pictures don’t do it justice, this took ages.

The vertical braces on each side behind the rear seat were the next target, each side came out without too much fuss. It was interesting to see areas where the welds has been blown through during original installation on the line.

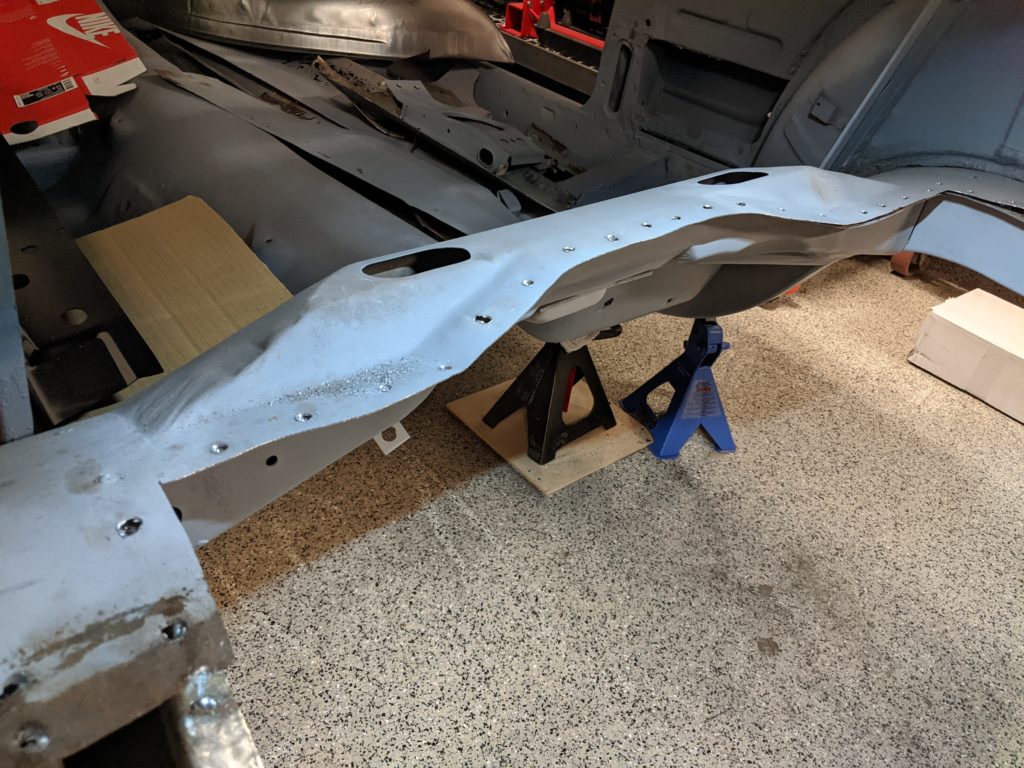

Good thing I decided to go ahead and replace the entire trunk floor, the rust damage under where the vertical supports connect to the floor was worse than I had known on both sides.

All of the angular shaping of this section of the trunk floor made it very difficult to peel back. I had to make liberal use of the pneumatic saw to work the remaining floor free.

asdf

After a full day of cutting and prying the remaining trunk floor excision was finally complete.