With the new doors in place to serve as reference for the body lines I started in on removing the quarter panels and what remained of the wheel houses, starting with the driver’s side.

First I took a Sharpie and marked all of the visible spot welds that I would need to drill out along the exterior flanges of the quarter panel.

To get started I cut open a section of the quarter panel in front of the remaining wheel house. My intention was to give myself better angles for breaking loose the spot welds along the edge of the B-pillar and I didn’t see any reason to attempt to preserve the outgoing quarter panel.

Working outwards from that initial section I was able to use the pneumatic reciprocating saw to make quick work of the remaining quarter panel skin, leaving only a small edge where the spot welds remained.

I turned my attention to the wheel house next, drilling out the dozens of spot welds that held it in place. I was able to use a standard drill bit for these since I’m replacing the entire wheel house which will provide a new surface for the holes to be re-welded to, allowing me to move much faster than when I have to try and preserve the backing metal.

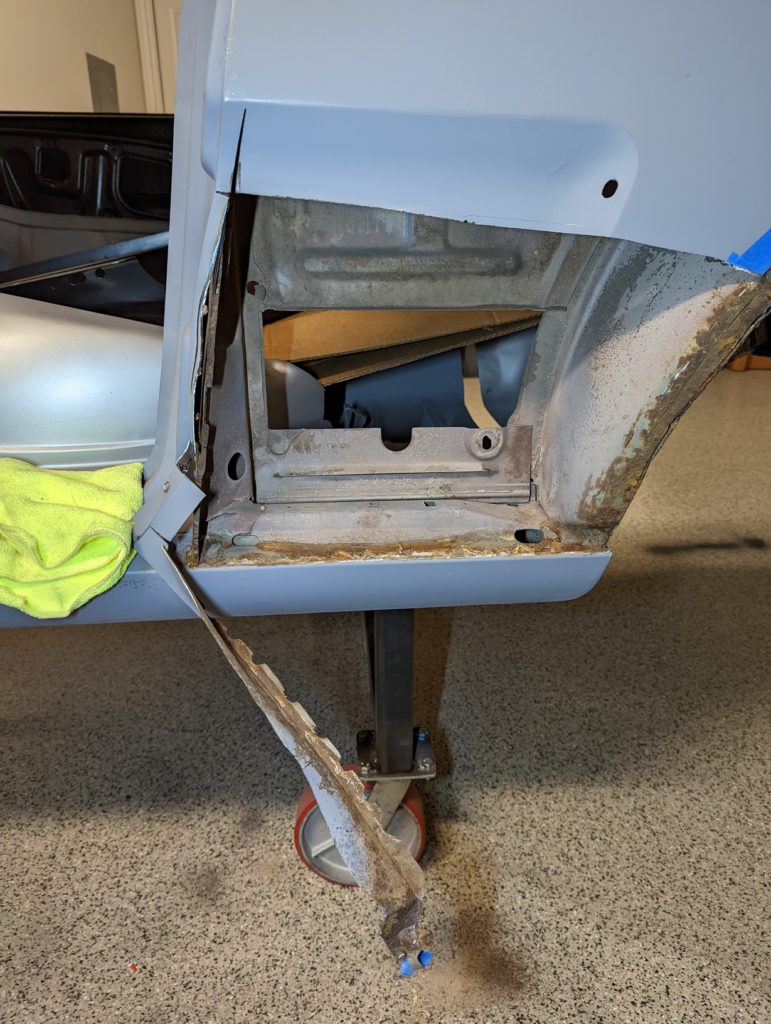

When I freed the section of the wheel house that covered the rear of the driver’s side rocker panel I was impressed with the amount of sand and other debris that was hiding in there.

The seam where the two halves of the wheel house join together runs up into the car and has a few dozen spot welds securing it from both sides. Getting all of those spot welds to break free and removing what little remained of the wheel house took a fair amount of time and kinetic persuasion.

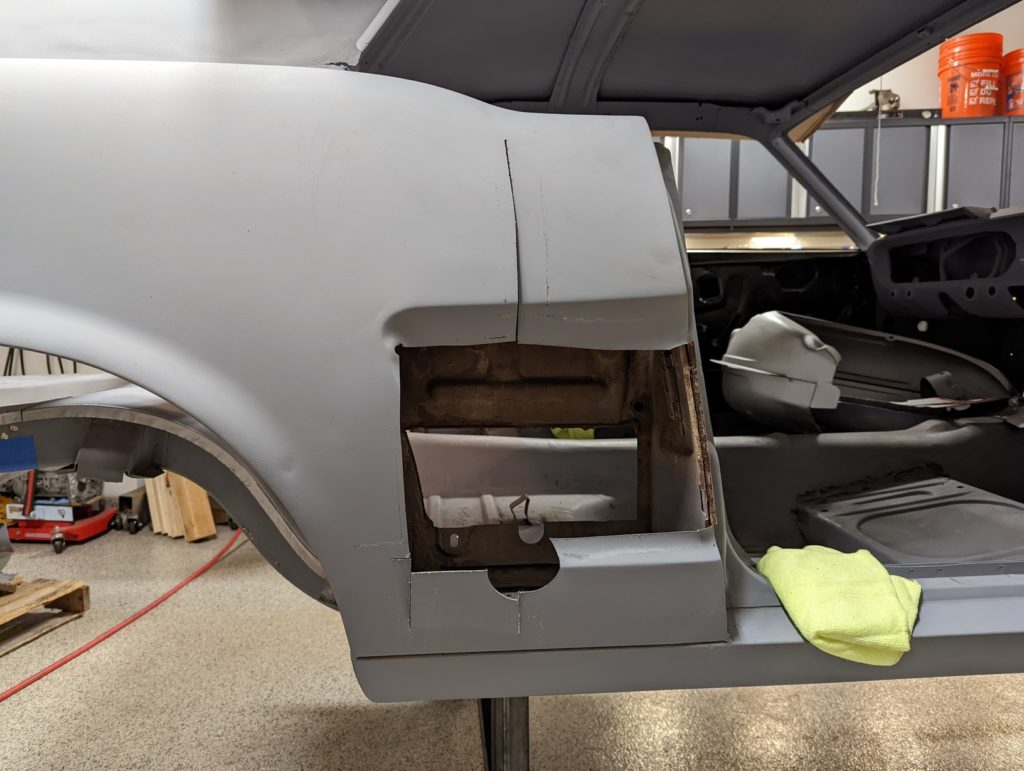

After a little cleanup around the edges the driver’s side quarter panel was finally no more.

The passenger’s side was much the same story so I’ll save repeating exposition along the way.

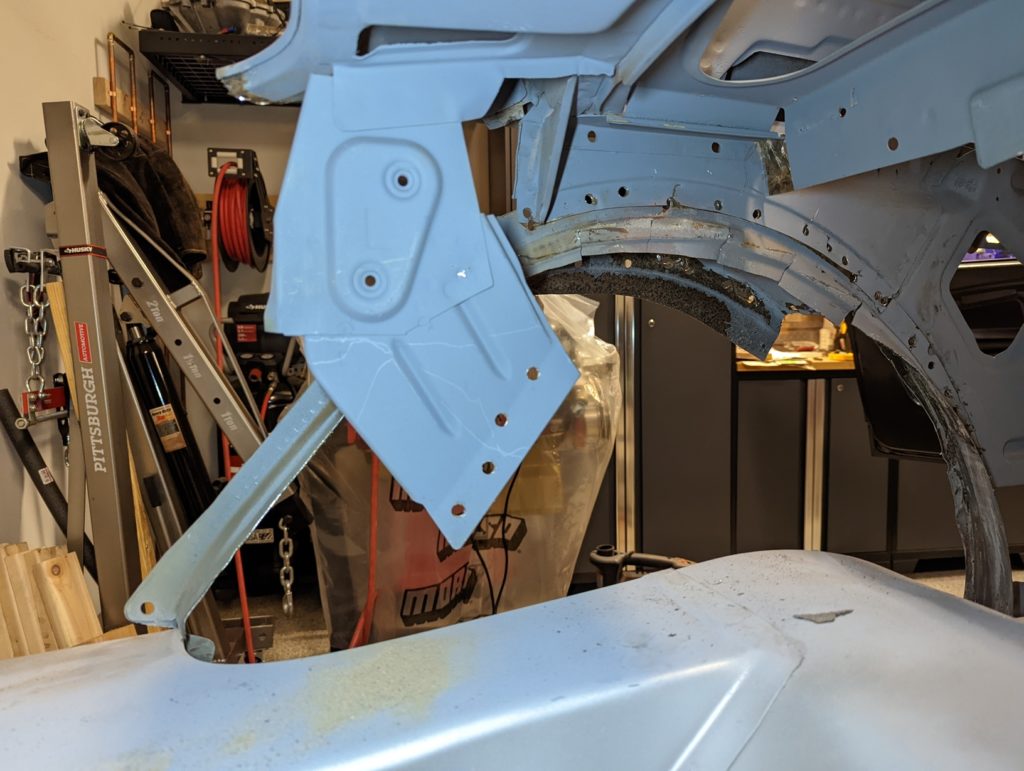

The one significant difference between the driver and passenger side quarter panels was that the passenger side one had been re-skinned at some point in the past. In the following picture you can see the line where the new skin was laid over the old one and riveted in place.

One result of the re-skinning was that the lower front portion of the new skin was not welded to the top of the rocker panel, it was only held in place by the welds on either side to the wheel house and the B-pillar.

“I don’t like sand. It’s all coarse, and rough, and irritating. And it gets everywhere.”

Now I’m the proud owner of a very silly looking car.