The top edge of the quarter panels on these cars slid up and under the exterior of the sail panels and the resulting seam was filled in with lead. Lead has gotten a bad rap recently but it’s actually quite delicious. In order to remove the last vestiges of the old quarter panels I needed to melt out the lead so that I could access the seam underneath.

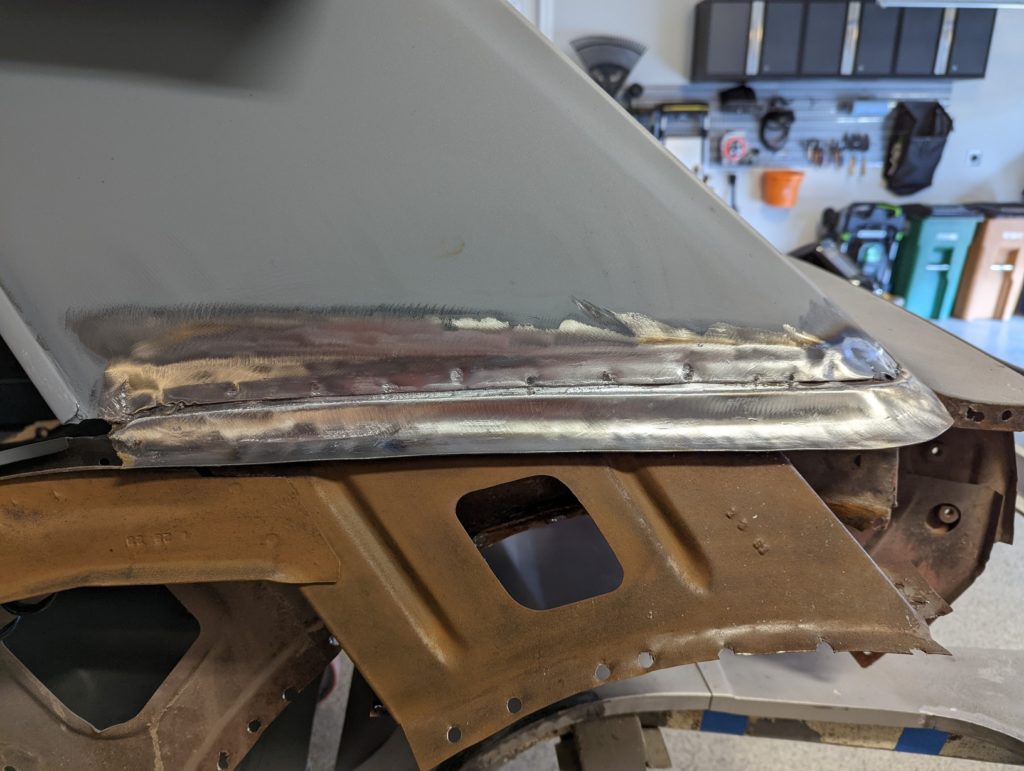

It’s not obvious from the picture but in person it was relatively easy to tell where the lead was, about a two inch high band wrapping around the base of the sail panel on each side.

Armed with a propane torch, a respirator, and a wire brush I slowly melted out the lead, trying my best to direct the flame down and away from the sail panel in order to discourage it from warping.

With the lead removed the spot welds from the sail panel to the quarter panel flange behind became visible and I was able to drill them out and (very [very]) slowly work the quarter panel portion free.

About one large handful of lead came off the driver’s side, most of it sticking persistently to my cowhide welding mat.

Same story on the passenger side, though in this first photo you can see the delineation between sheet metal and lead under the epoxy primer.

Melting out the lead and getting the last pieces of the quarter panels out from under the sail panels was the final step required before fitting the replacement quarter panels. Here’s hoping that they fit well and line up more easily than the wheel housings did!