The first order of business was getting the outer flanges of the wheelhouses to better conform to the shape of the corresponding flanges on the quarter panels.

I had split the driver side outer wheelhouse a while back, so I was able to use reversed clamps to force the outer flange of the wheelhouse out to match the quarter panel.

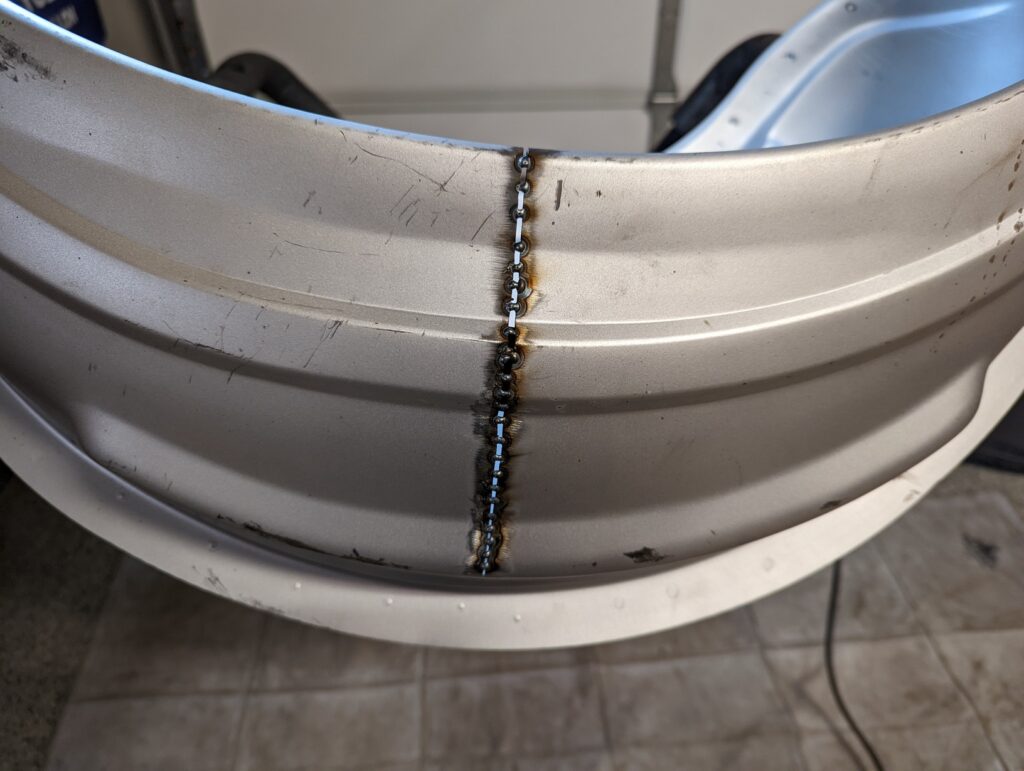

Once I was happy with the positioning I welded the wheelhouse back together.

After re-mounting the wheelhouse and checking the fit with the quarter panel, I decided to repeat the process one more time with a new split to further improve the fit.

The passenger side wheelhouse was a better fit with the quarter panel, but I still opted for a small split for outward adjustment.

With the wheelhouses sufficiently modified, I took the opportunity to spray Eastwood’s Internal Frame Coating in both rockers after cleaning out as much sand and junk as I could manage. Once installed the wheelhouses will cover the easiest access to the inside of the rockers.

After the rockers I cleaned up the unfinished metal surrounding the wheelhouses to the best of my ability and coated them in Eastwood’s Rust Encapsulator in an attempt to slow the hands of time.

The wheelhouses sported both some areas of bare metal and some spots that I thought would be difficult to spray after installation, so I decided to cover them in Eastwood 2k Epoxy Primer.

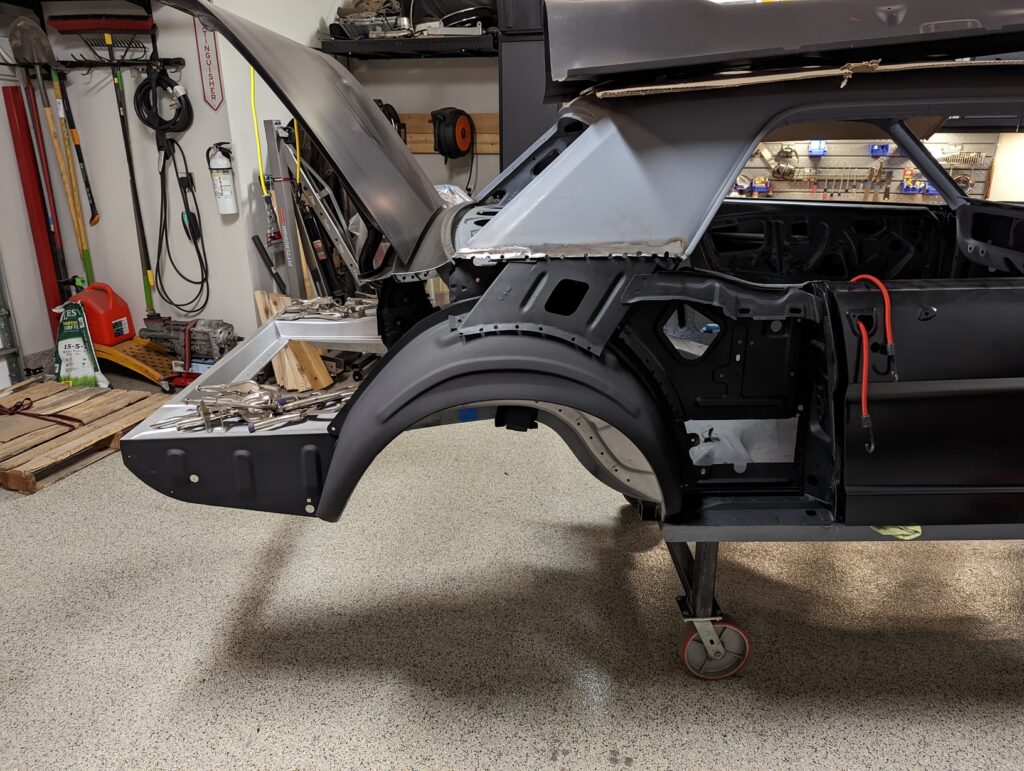

Grabbed a couple pictures of the final mounting of the primed wheelhouses prior to welding them in.

After massaging the surrounding mating flanges into shape and grinding off the primer under the spot weld locations, the tedious task of clamping and welding the wheelhouses in finally started. In the end it took nearly 8 hours to complete all of the welding across both wheelhouses.

Despite the fact that virtually none of the welds are going to be visible in the end, I couldn’t let them go without being ground flush.

Apparently I neglected to take pictures immediately following the completion of welding in the wheelhouses, so here’s one from a few days later when I was taking advantage of the re-welded trunk hinge mounts to test out the fit of the fancy aluminum trunk hinges I had picked up.

One step closer to having the backend back together!