In search of a change of pace, I decided to tackle removing the cowl. Looking back it probably would have been a good idea to wait to do this, but what’s a good project if not a series of new mistakes.

In addition to the clear rust damage on the sides, I knew that water would actively leak onto the toe boards through holes in the lower cowl.

As I was disassembling the car at the start of the restoration I found the cowl drains on each side clogged with pine needles. I’m sure that helped.

Nearly 200 spot welds to grind down. The 3/8ths belt sander and air chisel were godsends for this piece of the project.

Just like that, the top half of the cowl was peeled back to reveal the belly of the beast.

The passenger side actually wasn’t as bad as I had expected. Some pinholes here and there, but nothing obviously catastrophic around the hat.

On the other hand, the driver’s side revealed more damage than I had expected, with large holes into the interior of the car.

After I was done admiring the state of the lower cowl it was time to remove it as well.

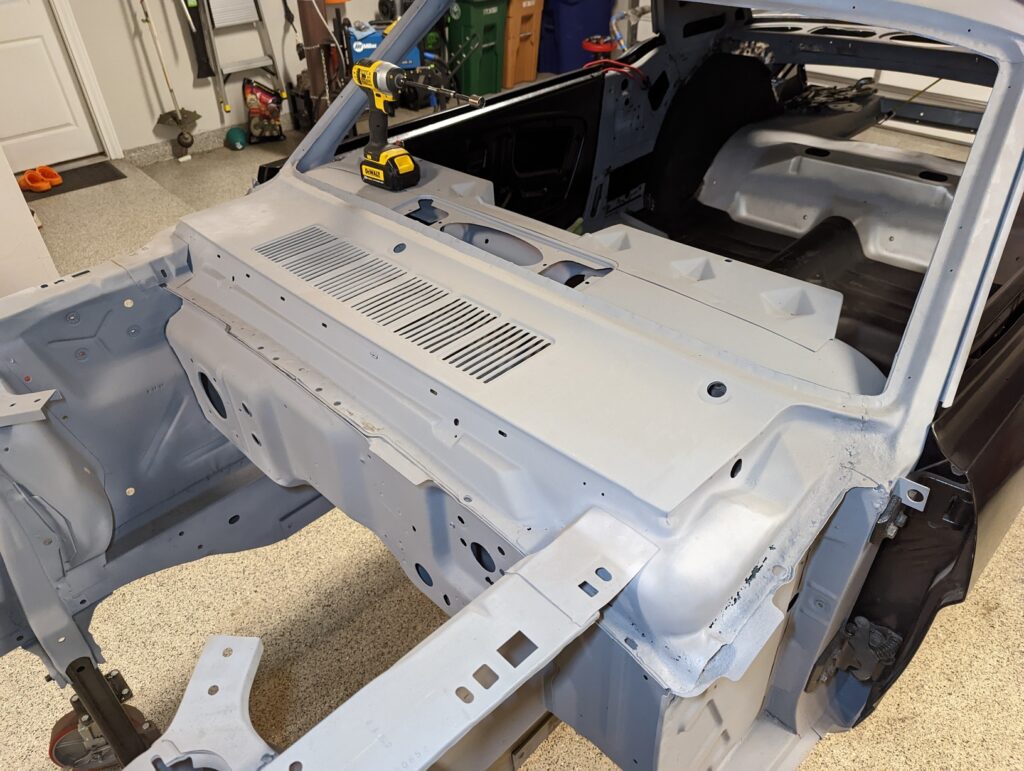

Well that looks pretty silly.

Removing the cowl made it obvious that the firewall had significant damage in the upper corners where it met the cowl. I’ll have to shore those areas up, but not today.

Before I called it a day I tossed the new two-piece cowl on just to make sure it looked like it might fit given sufficient persuation.