The day finally arrived, just a few steps away from being able to weld the tail panel back together and onto the car.

Since I decided to re-use the original tail panel corners, I started off with cutting out and patching the small portions that still had braze on them.

My frankenstein tail panel has new metal along the entire bottom edge of the panel, meaning that the original screw holes from the rear valence no longer existed. Since they did exist in the trunk lip behind where the bottom of the tail panel mounts, I decided to try to copy their locations over to the tail panel by using blue tape overlaid as a sort of template. Unfortunately this didn’t end up working particularly well due to a lack of precision, I ended up having to weld up and re-drill about half of the holes.

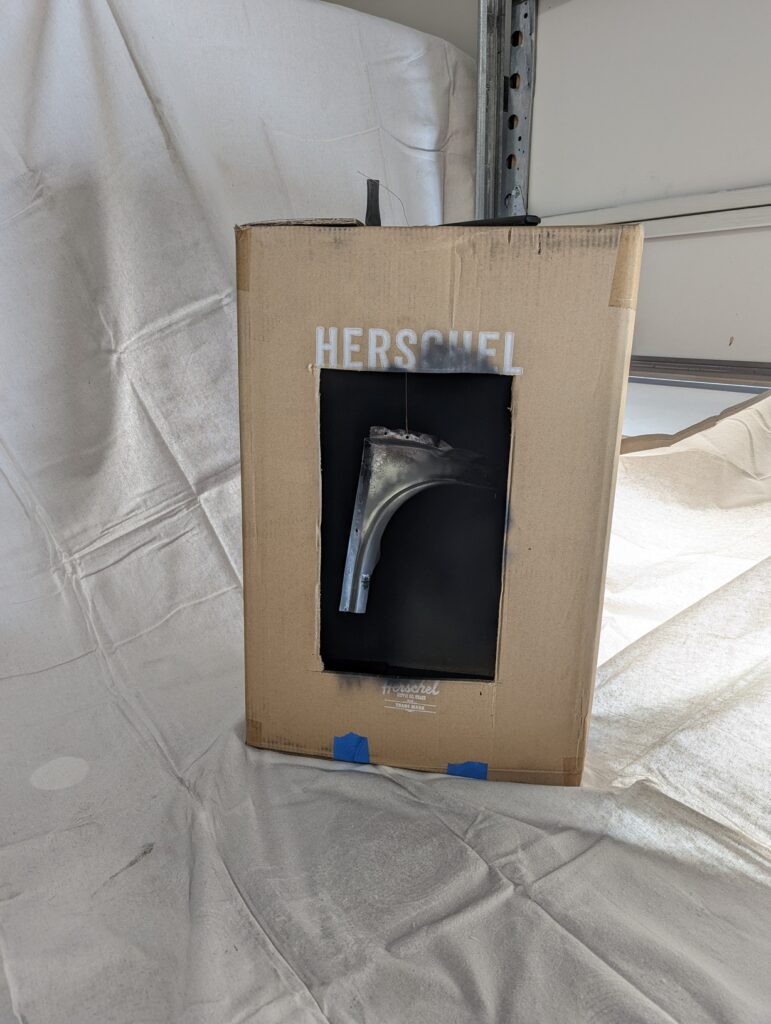

The tail panel corners and quarter end caps took turns getting cycled through my professional paint booth for a coat of rattle can primer.

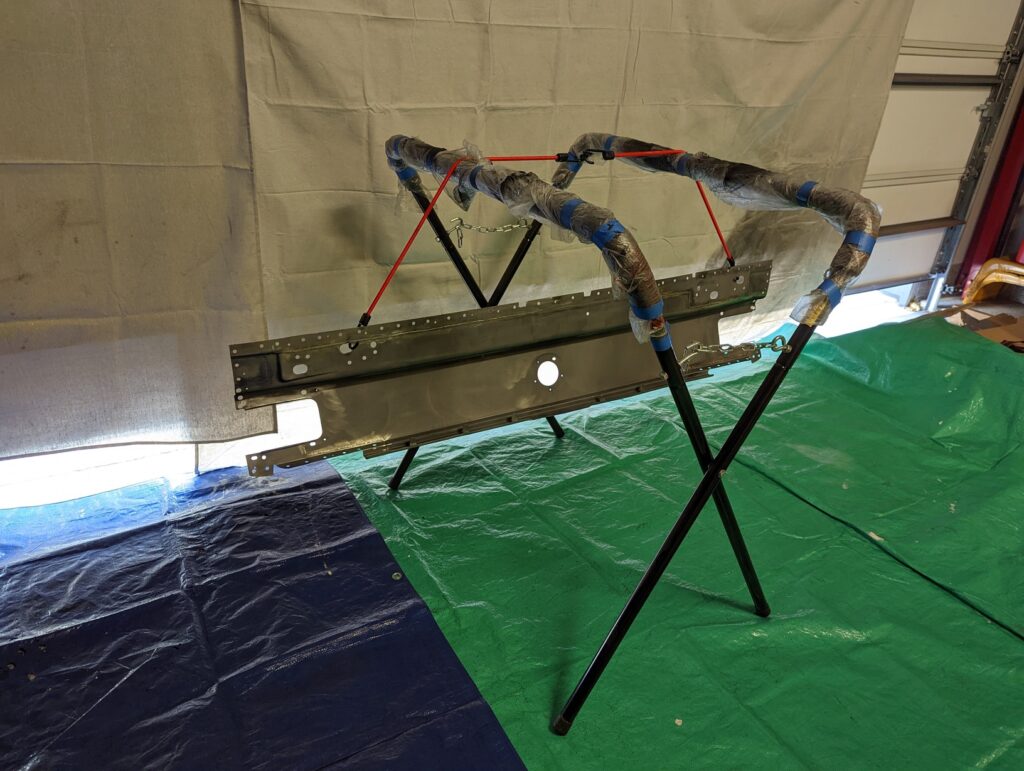

When it was the tail panel’s turn I looked at it and thought “there has to be a way I could get to both sides so that I don’t have to wait for one side to dry completely before flipping it over”

Thank god for bungee cords.

Not pictured: when I decided to hang it to dry from the garage door rails and thought “as long as my wife doesn’t open the garage this should work fine”, and then opened the garage myself 20 minutes later, causing one of the bungees to come off and one corner of the tail panel to slam into the ground. Thankfully the corner bent in such a way that it was easily corrected with a hammer and dolly. Whoops.

After drying the tail panel was the first piece ready for final mockup.

I opted to weld the tail panel corners and quarter end caps together off the car, felt like it would make things a little easier by removing some degrees of freedom as far as movement between the various pieces was concerned.

Final fitment checks before starting to weld the components together into their final resting places.

I started welding the tail panel in the middle, moving out toward each of the edges. Never enough sheet metal clamps.

With the tail panel welded in across the bottom of the panel I wanted to get the trunk latch bracket welded in to give the tail panel vertical support and to keep the angle of the tail panel steady while welding everything else together.

Just like that, the tail panel was finally cemented in place.