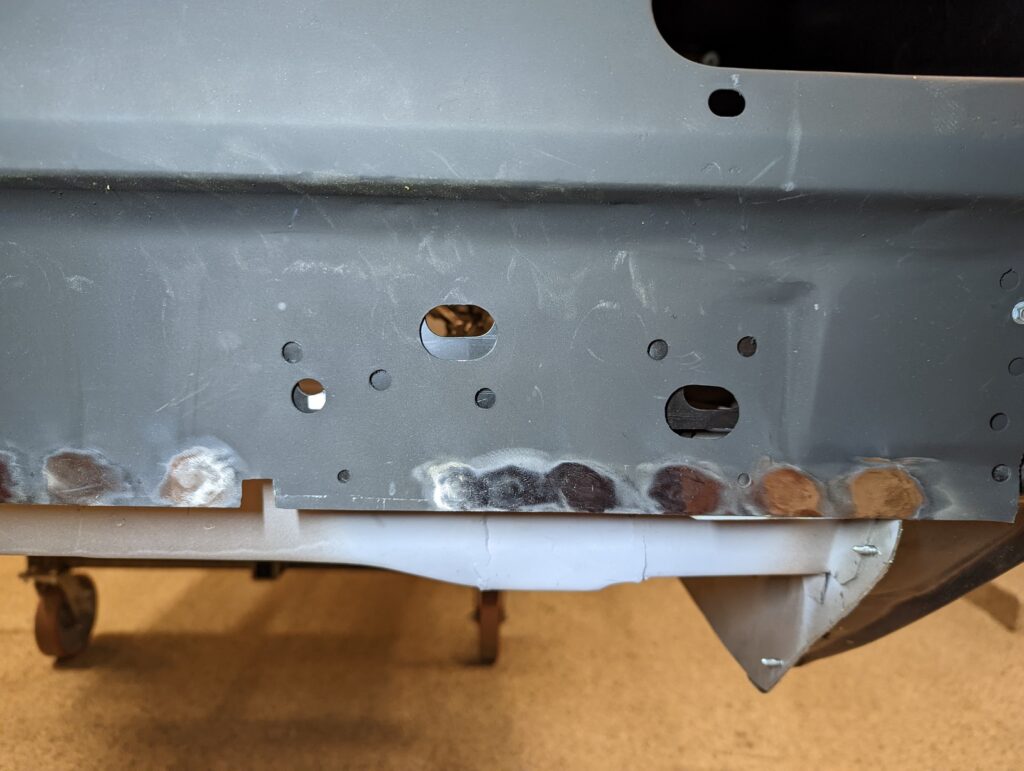

The best part about buying a bunch of reproduction sheet metal from the same manufacturer and vendor is that none of them fit together. The latest example was the rear bumper mounts that sit flush with the back side of the tail panel. Each mount has a couple holes for the rear bumper to mount to, none of which were particularly close to matching the holes in the tail panel on either side of the car. As far as the tail panel is concerned, one set of holes is from the original sheet metal while the other side is from a reproduction panel, there was no observable difference in fit quality between the two.

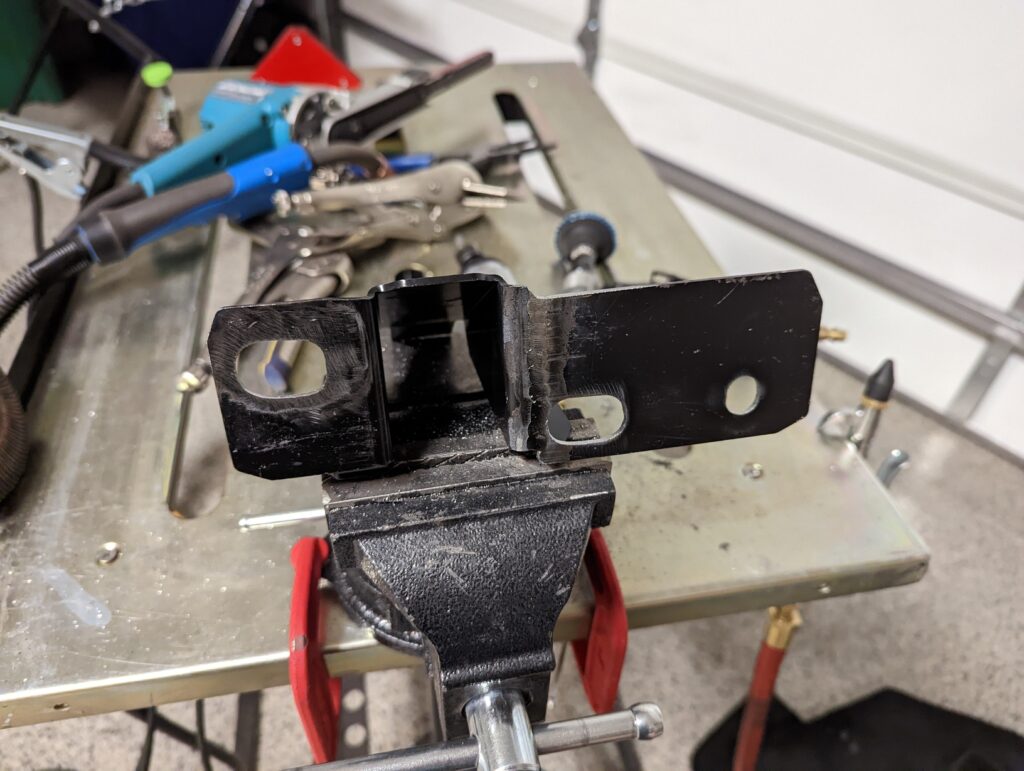

Time to modify the mounts to fit.

In addition to having holes that didn’t align well, the faces of the mounts weren’t even straight. Step one was flattening those out so that the mount would sit flush with the back of the tail panel.

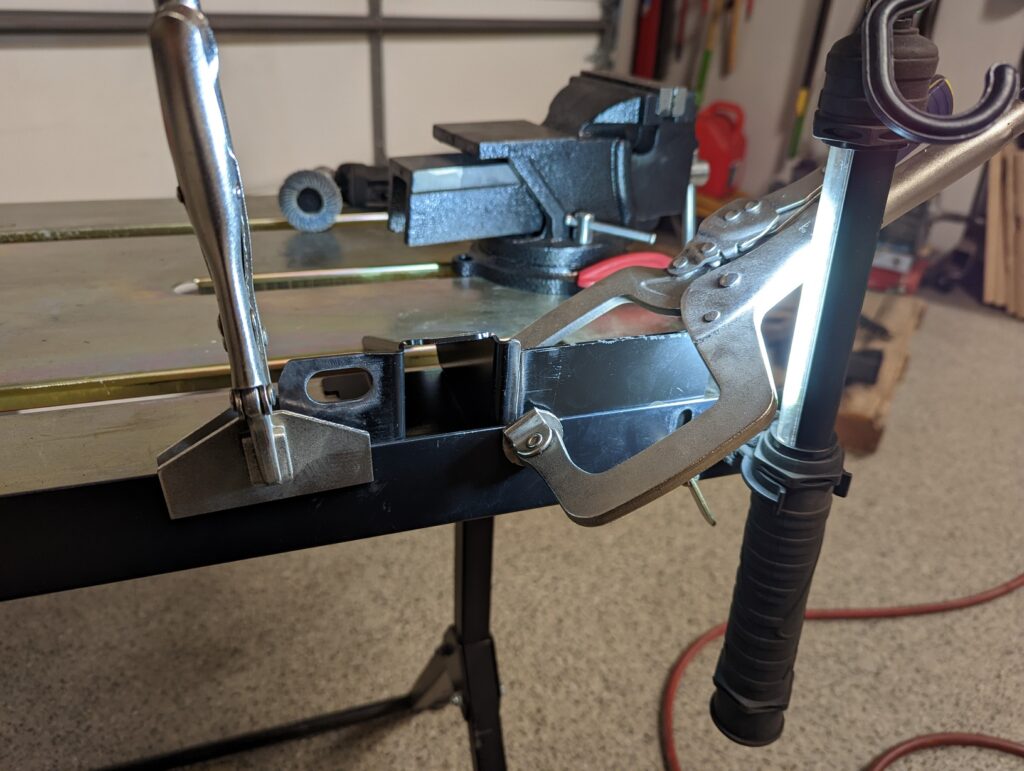

I cut the longer side of the mount entirely off so that I could move it down ~1/3″ and then weld it back together. This was the furthest I could lower it before the bottom edge would be lower than the mount base and prevent the mount from sitting flat against the trunk.

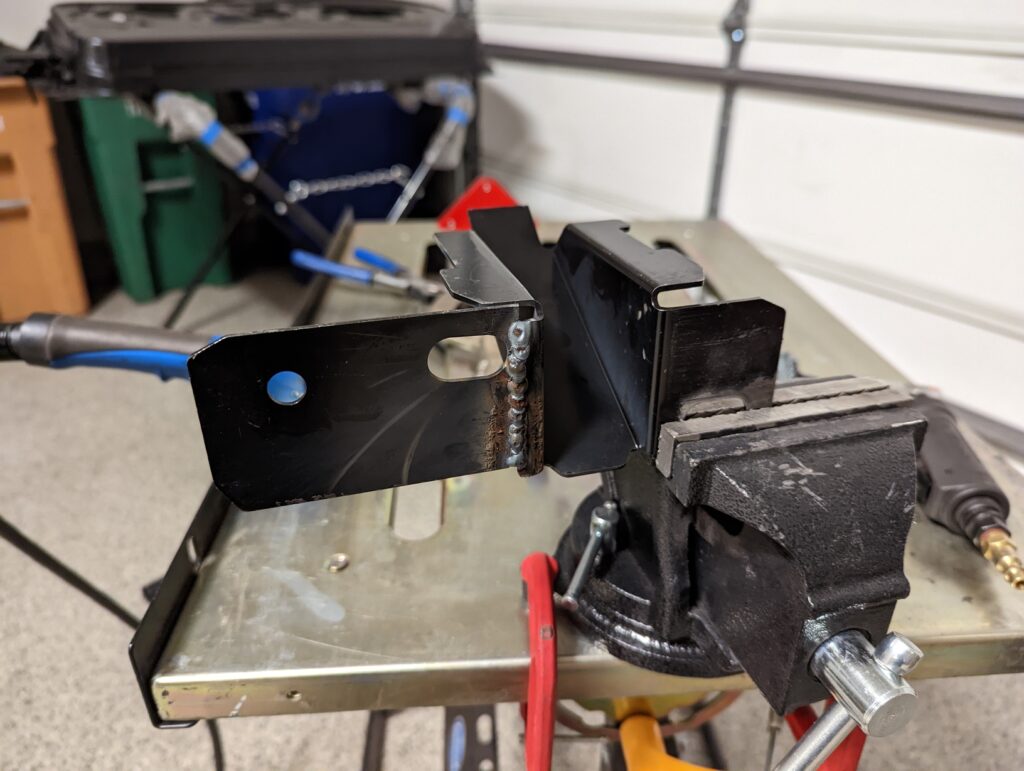

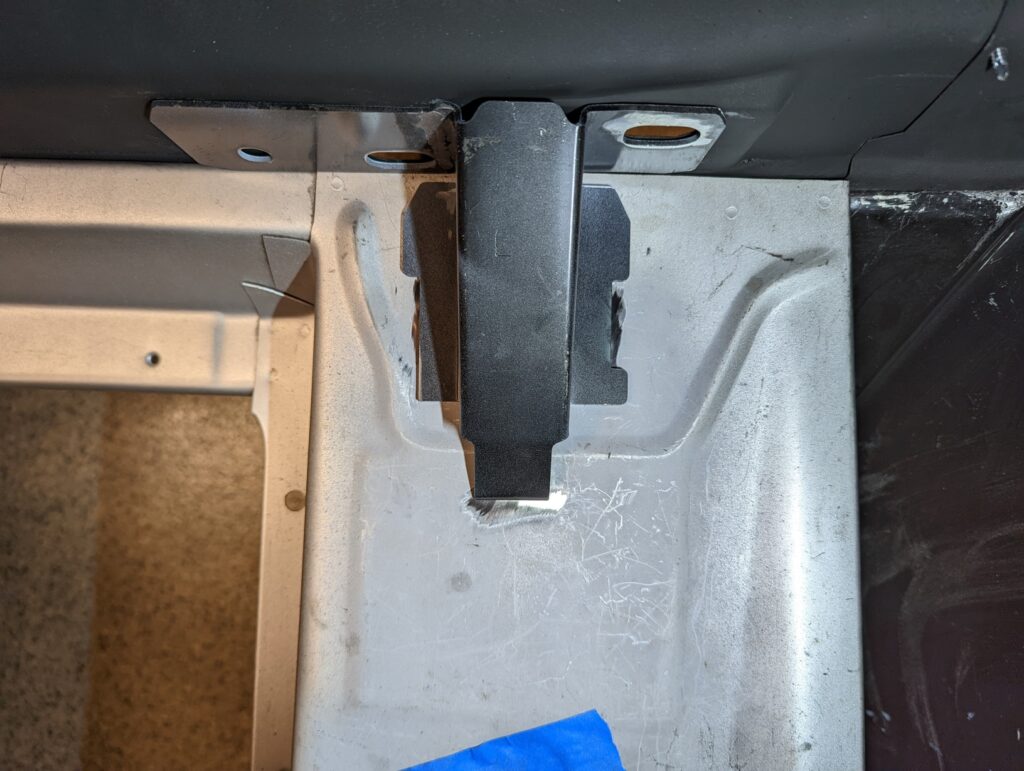

That got one side pretty close, unfortunately the other side didn’t have enough room to be dropped far enough, so I settled for welding up the existing hole and drilling out a new one.

After filling the existing hole I traced the outline of the hole in the tail panel onto the mount using a Sharpie.

After a bit of drilling and die grinding the new hole was lining up nicely.

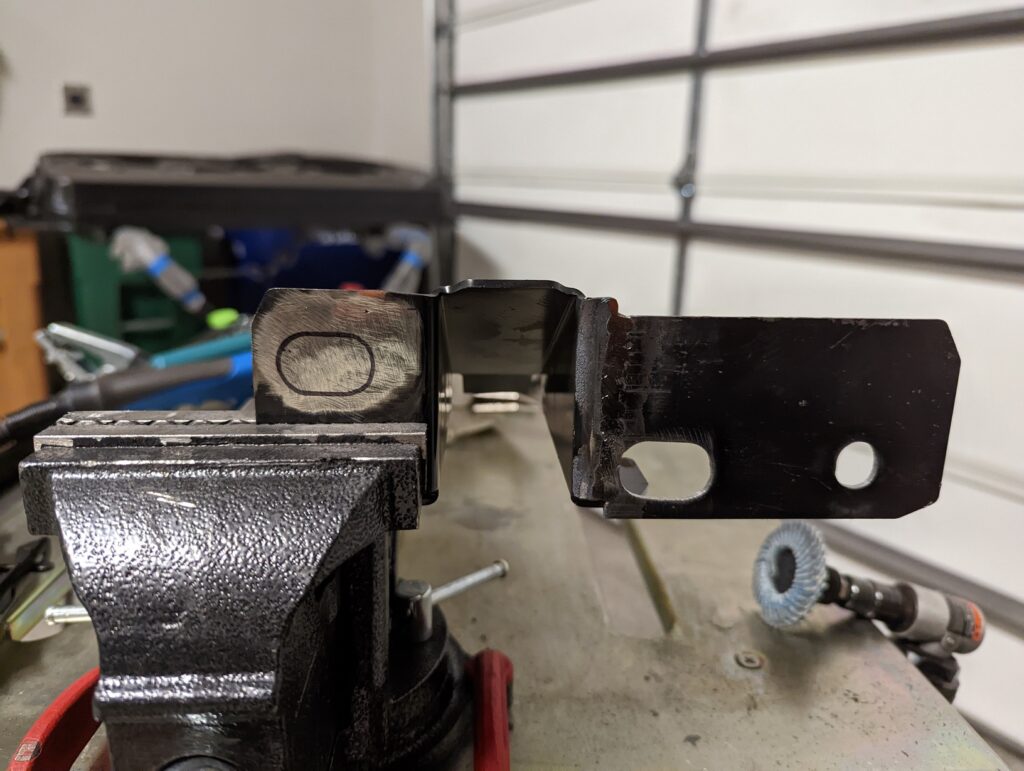

One side done, one to go.

The remaining side was a mirror image of the same story.

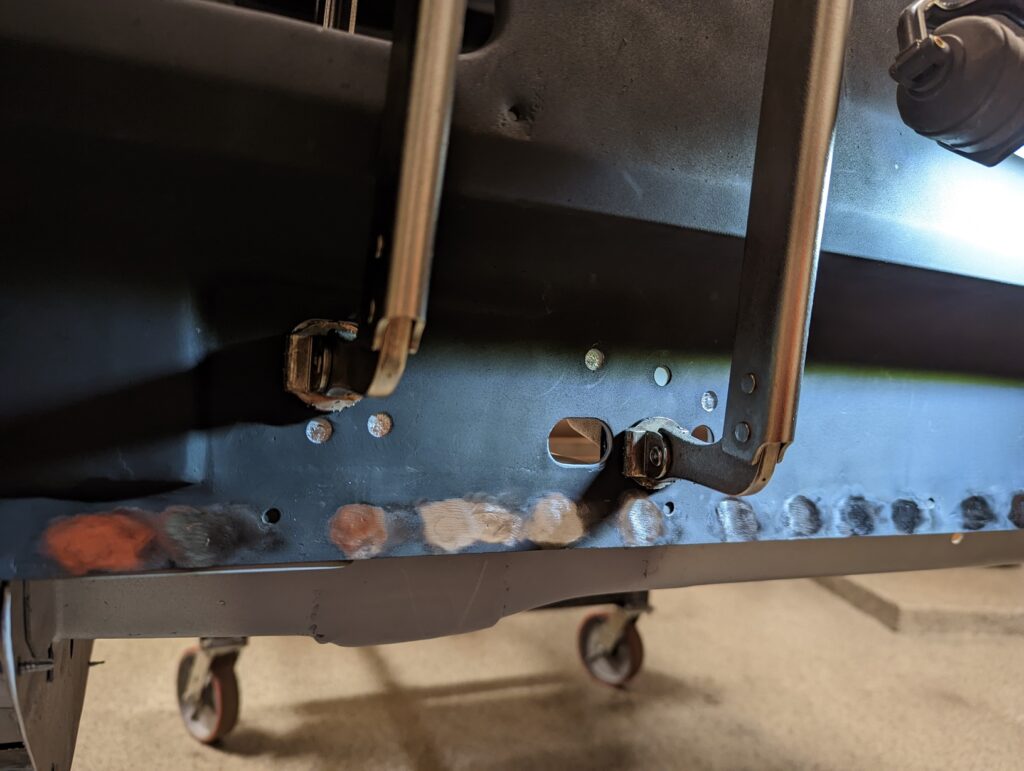

With both mounts successfully modified I went ahead and sprayed the faces in weld thru primer.

The mounts weld to the trunk floor along each side and in the back, so I the primer off of those areas in preparation for welding.

Rinse and repeat on the other side and that’s the bumper mounts complete.