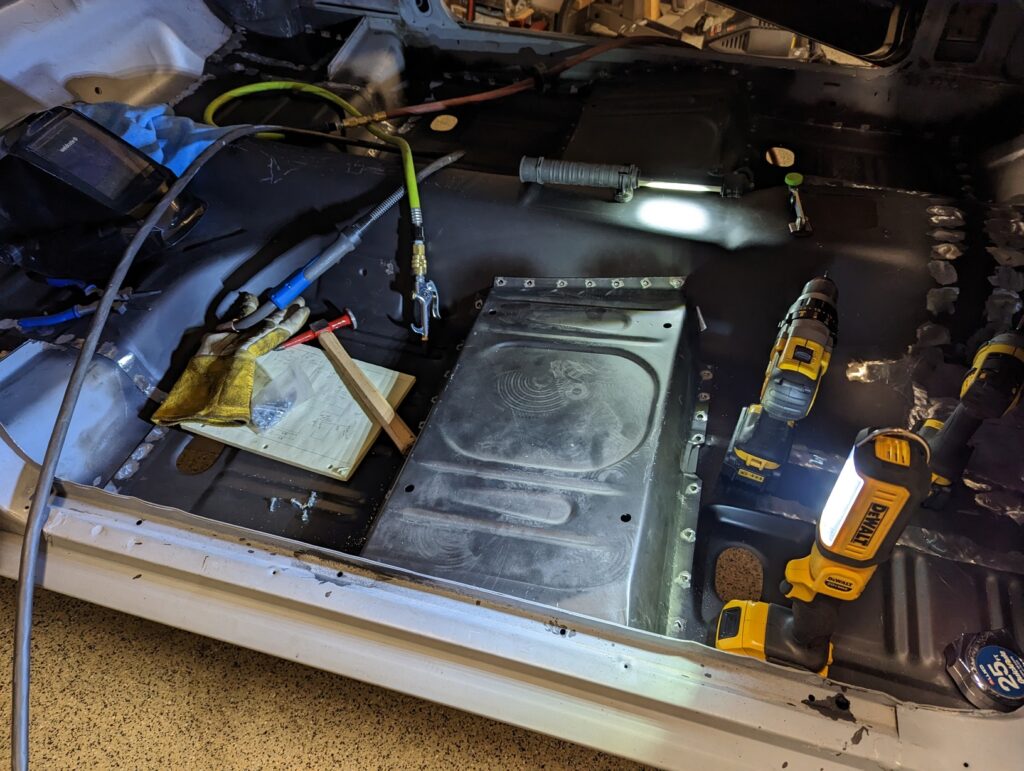

The completion of the floor install meant that the seat risers were up next! I dropped them in place and stood on them to try and get them to flex into shape. On the driver’s side I still ended up with a gap at the back right corner that was just large enough for me to slide my pinky under.

I determined that the seat riser wasn’t sitting down far enough because the flanges against the transmission tunnel were sticking out too far. In order to bring them in a bit I cut off both flanges and then re-welded them slightly inset from their original positions. Doing so gave me the clearance needed to close the gap between the bottom flange of the riser and the floor.

The passenger side riser required less significant modification, tweaking the angle of some of the flanges was sufficient to achieve a solid fit.

After drilling out the spot weld holes I coated the inside of both risers with paint since that area wouldn’t be particularly accessible once they were installed.

I made sure to double and triple check my measurements for locating the risers prior to tack welding them in place. So far in this project whenever I take measurements I think I’m taking way more than I’ll ever need and when I read my previous measurements I wonder why I took so few.

A bit of welding later and the seat risers were complete!

Doesn’t matter, had seat.