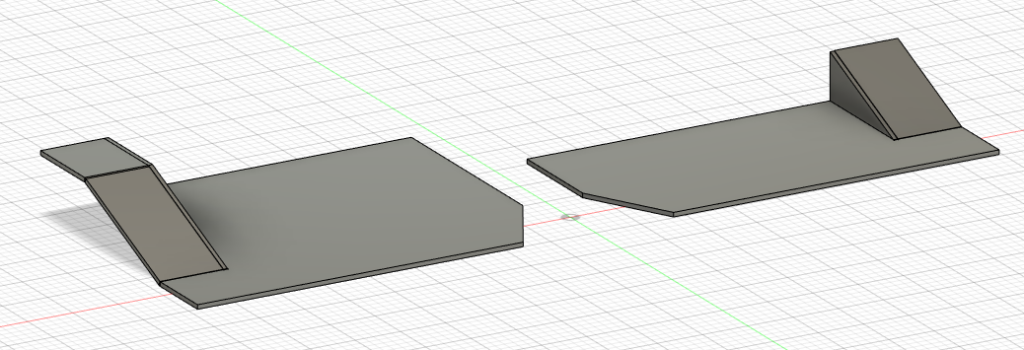

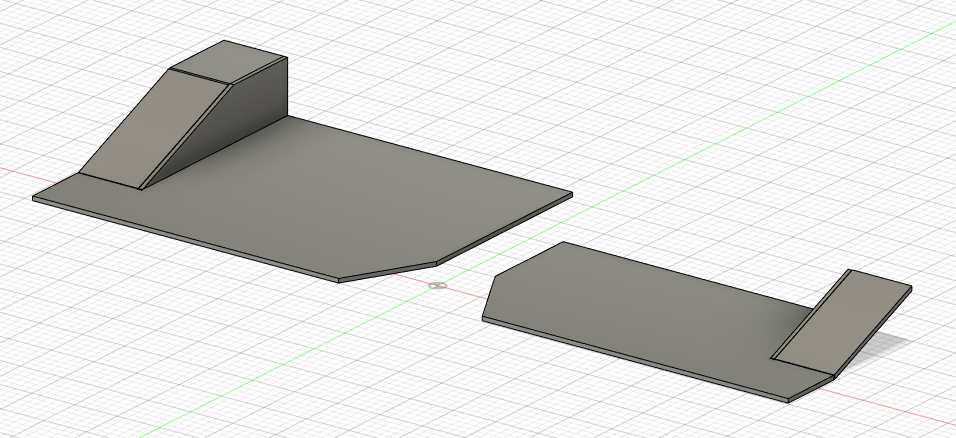

The rear seat support brackets both sported rust damage near the bottom where they attached to the floor. Rather than recreate the sections by hand I decided to attempt drafting them up in CAD and then having an online laser cutting shop cut the steel and ship it to me.

The company that I ordered the laser cutting through was able to replicate the required bends in the sheet metal, all I needed to do was to weld in the vertical faces.

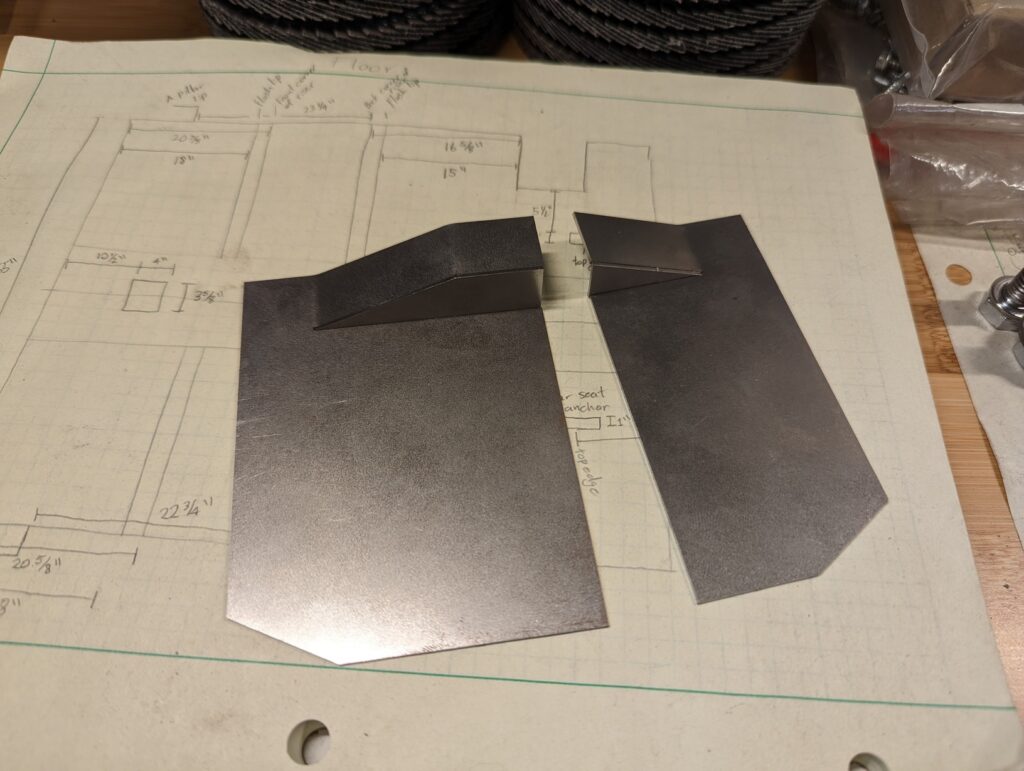

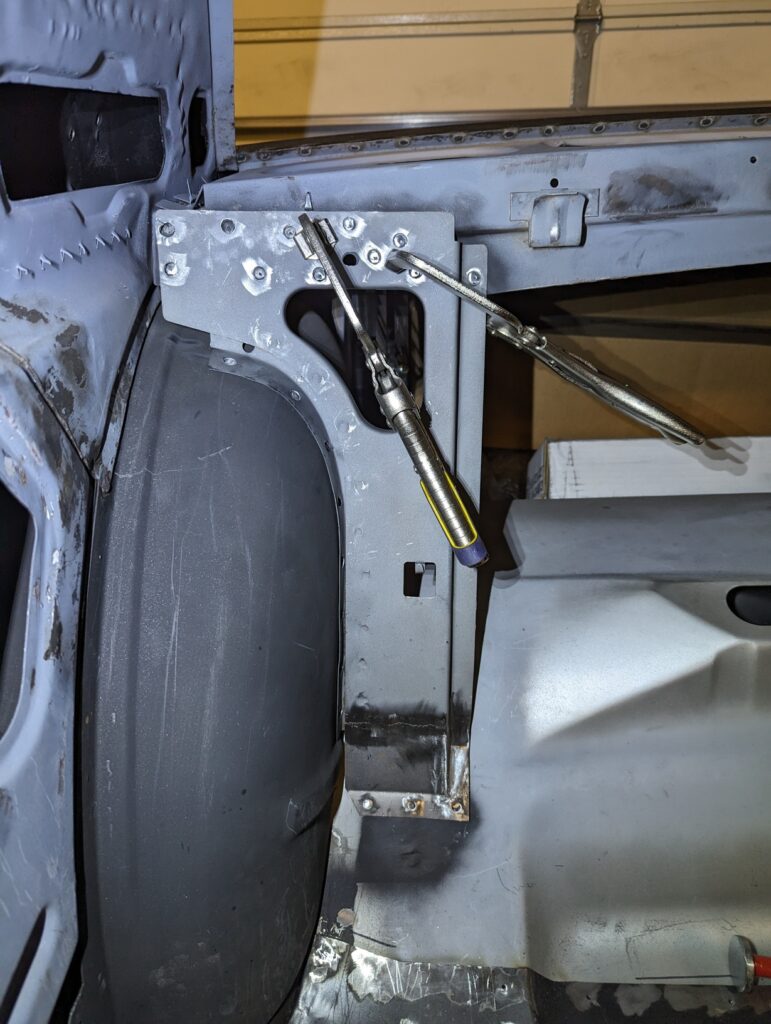

Mocking up the laser cut pieces prior to cutting the rusted sections off the brackets.

The next order of business was to cut off the rust damaged portion so I could dry-fit the new metal in earnest.

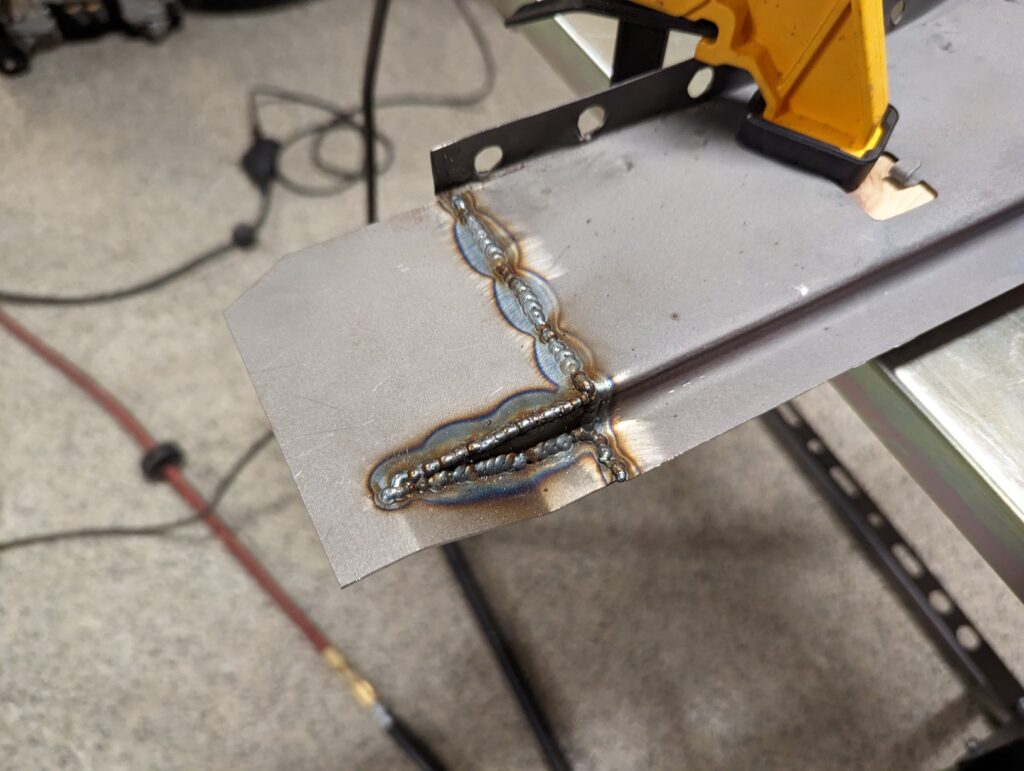

Everything looked great so I held it all together with a couple magnets while I tack welded it together.

After some grinding it was time to move on to repeat the process with the second bracket.

With the brackets repaired I was able to go ahead and reinstall them back in the car. The wheel house flanges needed some mild adjustments, everything else was relatively easy thanks to being able to align the brackets with the original spot weld locations in the speaker tray.

I’m super happy with the way the laser cut pieces worked out. Since I’m better at CAD than metal fab I’ll definitely look to use that approach again if the proper situation arises.